LUMIK

Main Features

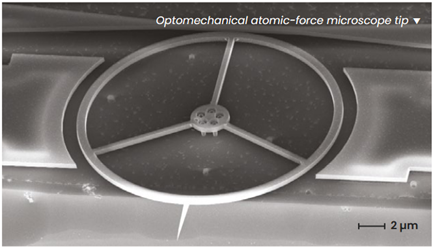

- Optomechanical technology combining silicon photonics and and high-performance MEMS (Micro Electro-Mechanical Sensors) for motion detection using light.

- Principle based on the interaction between a MEMS resonator and an optical cavity – the movement of a mass generates an intensity variation that allows it to be measured.

- Increased sensitivity, higher speed, and optimized integration compared to traditional capacitive and piezoresistive technologies.

Process Characteristics

- Combination of VLSI (Very Large Scale Integration) optical and mechanical processes

- 200mm wafer size – Grenoble facility (France)

- SOI substrate

- Optical IO patterned by DUV (Deep Ultra-Violet) lithography and formed by dry etching

- MEMS resonator, photonic devices and electrical contacts defined using e-beam lithography and formed by RIE (Reactive Ion Etching)

- 1 AlSi metallization level for polarization and interconnections

- Resonator release by isotropic HF etching

Device Characteristics and key figures

- Minimum feature size of 100nm for both optical & mechanical parts

- Operating optical wavelength of 1550 nm

- Femtometer detection capabilities

- Response rate in the terahertz range

- Scalability of VLSI MEMS and silicon-photonics technologies

Prices

The details about the prices will come soon.

Contact

Design-Kit Content

- Standard cells of basic devices to start a design and illustrate the use of CAD layers

- The standard cell libraries will be gradually extended with each new release of the design kit

CAD Tools

Cadence

- IC (design framework)

Siemens

- Calibre (physical verification)

Usual Application areas

- Portable in-situ mass spectrometry (extreme sensistvity down to viruses and proteins)

- Portable biological sensing (rapidbiomarker detection and sensitvity down to bacteria)

- Real-time atomic-force microscopy (video-rate imaging to observe fast biological process)

- Silicon clocks (quartz-like accuracy for GHz frequency)

- Inertial sensors (precision and compactness)

- Quantum information transfer

- Rheology

Run Dates

- First submission deadline to CIME-P in February 2026 for first run

- More details to come in the near future

Turnaround Time

- 44 weeks for manufacturing